Well, Since I got rid of my DSM, I'm going to turbo my SC400...

I've grown out of needing a car that traps 140, but lets be realistic - a sctock sc400 is freaking SLOW...

So, here's the idea, and I'm looking for any insight...

First off, I'll tell everyone this - I have full access to a fabrication shop, so I can build pretty much whatever I need, that can't be bought off the shelf...

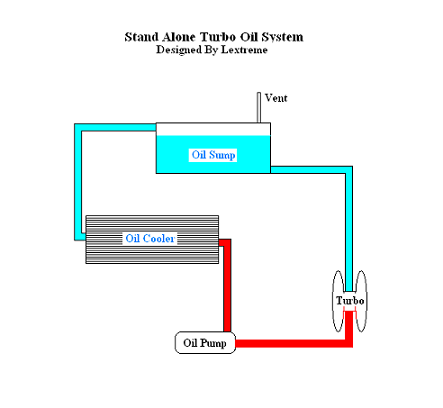

Ok, so, take a stock SC400, leave the stock headers/manifolds on the car, remove the two cats in the downpipe location, and fabricate a custom Y-pipe with a T4 flange on the end. Mount the turbo in the location of the stock main cat. Feed oil from the engine to the turbo via -3 or -4 an stainless line. Oil will flow out of the turbo into a small reservoir, which will have an electric oil pump mounted to it to move oil back to the engine. Inlet piping will come from the fenderwell area, and charge piping will route back into the engine compartment with a small air to water intercooler with a radiator for it mounted in the front fenderwell. A 40 mm wastegate will be utilized, and a 50mm Tial BOV as well...

The turbo I want to use is a 60-1 (maybe a 62-1) with a .68 a/r T4 hotside, as the compressor map shows 70% efficiency at 1.6 pr (8.8psi charge outlet) and flowing just over 45 lbs/min airflow... According to these specs, and assuming a little over 1 psi pressure drop over the IC, we can have 7.5 psi at the motor, a cool intake charge (charge temps will be less than 200 degrees BEFORE the IC), and make 450 crank hp on a good tune...

Any ideas, nags, bitches?

Better yet, what would someone pay for a BOLT IN kit like this? I am thinking it can all be done, turbo, ic, piping, radiator, pump, and all for around $3000...

I've grown out of needing a car that traps 140, but lets be realistic - a sctock sc400 is freaking SLOW...

So, here's the idea, and I'm looking for any insight...

First off, I'll tell everyone this - I have full access to a fabrication shop, so I can build pretty much whatever I need, that can't be bought off the shelf...

Ok, so, take a stock SC400, leave the stock headers/manifolds on the car, remove the two cats in the downpipe location, and fabricate a custom Y-pipe with a T4 flange on the end. Mount the turbo in the location of the stock main cat. Feed oil from the engine to the turbo via -3 or -4 an stainless line. Oil will flow out of the turbo into a small reservoir, which will have an electric oil pump mounted to it to move oil back to the engine. Inlet piping will come from the fenderwell area, and charge piping will route back into the engine compartment with a small air to water intercooler with a radiator for it mounted in the front fenderwell. A 40 mm wastegate will be utilized, and a 50mm Tial BOV as well...

The turbo I want to use is a 60-1 (maybe a 62-1) with a .68 a/r T4 hotside, as the compressor map shows 70% efficiency at 1.6 pr (8.8psi charge outlet) and flowing just over 45 lbs/min airflow... According to these specs, and assuming a little over 1 psi pressure drop over the IC, we can have 7.5 psi at the motor, a cool intake charge (charge temps will be less than 200 degrees BEFORE the IC), and make 450 crank hp on a good tune...

Any ideas, nags, bitches?

Better yet, what would someone pay for a BOLT IN kit like this? I am thinking it can all be done, turbo, ic, piping, radiator, pump, and all for around $3000...